|

|

90M-T-1,2LD Soldering Tip

90M-T-1,2LD Soldering Tip

|

|

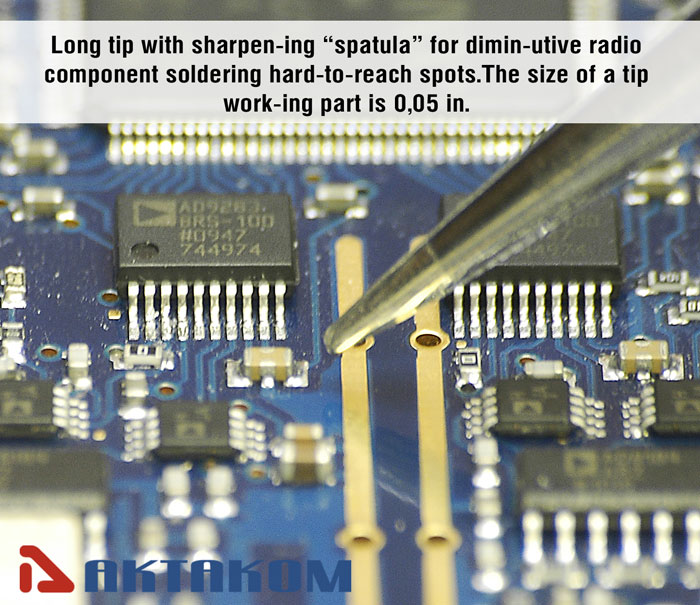

Long tip for soldering stations ASE-1101, 1102, 3101 with sharpening “spatula” for diminutive radio component soldering hard-to-reach spots

|

|

Long tip for soldering stations ASE-1101, 1102, 3101 with sharpening “spatula” for diminutive radio component soldering hard-to-reach spots

The size of a tip working part is 0,05 in

Soldering tips are made of oxygen-free copper with the steel center and nickel-chromic external covering, the correct use secures a long service life. The long exploitation term of the tips is gained due to their multilayer structure in which the external layer (chrome) is protective, internal (copper) is responsible for heat conductivity, intermediate (steel) - for durability and long operating life. And a working part (tin) - for good solder wettability.

Attention!

- Multilayered Soldering tips don’t need any sharpening.

- Unreasonable high temperature shortens service life. Use the minimal acceptable temperature, if possible.

- Soft tip cleaning from carbon is made whith a damp cellulose sponge as oxide and carbides of solder and gumboils can pollute a tip affecting the soldering quality and decreasing the heat transfer.

- During continuous work, it’s necessary to take the tip off and to complete cleaning from oxides no less than once a week. Solder on the tip must stay even in a cold condition.

- Do not use aggressive soldering flux, consisting of chlorides, or acid. Use colophony flux.

| 90M-T-1,2LD Soldering Tip |

|

|

| 90M-T-1,2LD Soldering Tip - Soldering tip structure |

|

|

| 90M-T-1,2LD Soldering Tip - Application |

|

|

|

For diminutive radio component soldering in hard-to-reach spots

Back to the section

|

|